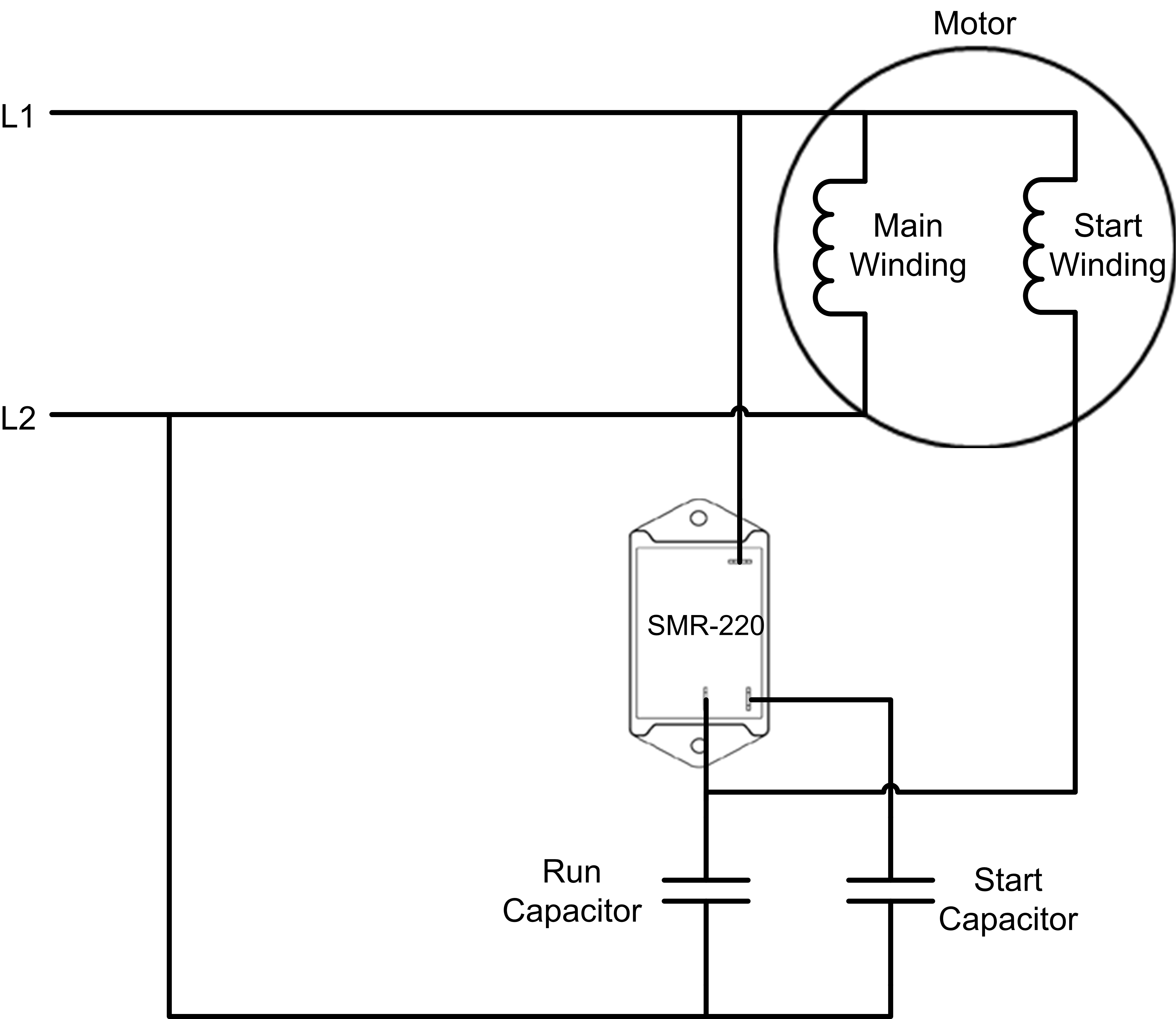

Typically, some motors and compressors need high starting torque. To generate a high starting torque a high starting current is needed, which can be generated by connecting a start capacitor in series with the motor’s start winding.The start capacitor must be disconnected as soon as the motor speed reaches 75% of its full load speed. Keeping the start capacitor connected will produce a high current that would destroy the start winding. For this reason, it’s important to have to reliable device to disconnect the start capacitor accurately.

SMR-220 solid state relay is a patent pending electronic replacement for potential starting relays which are used with single-phase capacitor start motors. SMR-220 electronically senses voltage across the start winding. When the voltage passes a certain level the relay disconnect the start capacitor from the start winding. Compared to mechanical potential relays, SMR-220 is more durable and reliable. Since it can tolerate more voltage and current spikes, it has a longer lifetime.